- Home

- Product Catalog

- Pattern Press

- Cutting Machine

- complex machine

- Sewing machine

- Stripping Machine

- Needle Detector

- Embroidery Machine

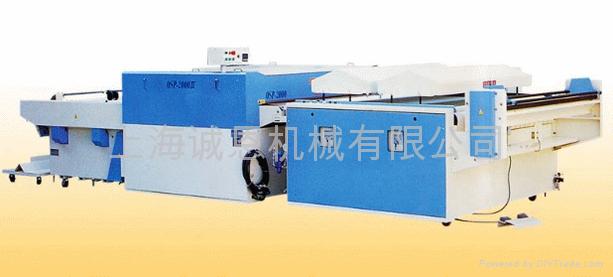

- Serial Fusing Machine

- Cloth Inspecting Machine

- Raab Machine

- Custom Page

- Shoes Machine

- Trademark machinery

- Security equipment

- Arm Cutting Machine

- Embroidery Machine

- Automatic cutting

- 16-color embroidery machine

- Automatic cutting cloth machin

- Laser cutting equipment

- hollow glass

- Engineering Fracture Crusher

- News

- Contact Us